With the growth of our industries, we are compelled to optimize our production cycles to make our processes more efficient. From raw materials to tooling, we aim for quality and efficiency in a cost-effective manner.

As we focus on developments in the plastics industry, there are a number of aspects to consider. The plastic industry has been making huge strides over the past few years. Plastic injection molding is a good example of this. Historically, it dates back to the end of the 19th century. The concept of injection molding was first conceived by John Hyatt and Isaiah Hyatt.

The idea has developed since then to the point of incorporating automation into the cycle.

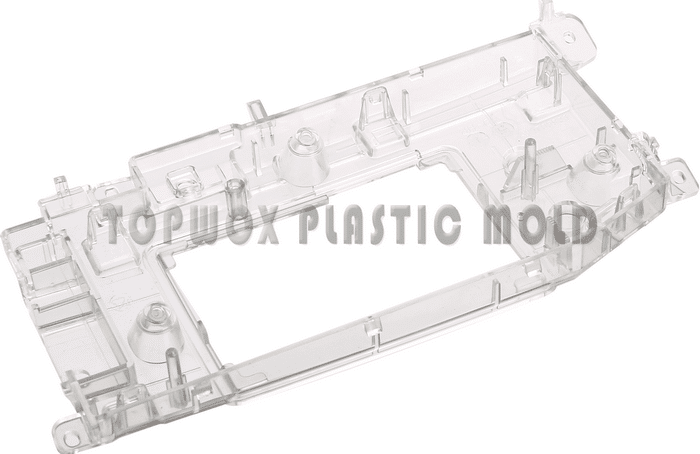

Injection molding now uses polycarbonate as a raw material. Injection molding of polycarbonate is growing in popularity due to its many benefits.

Polycarbonates: what are they?

Properties and Characteristics of Polycarbonates

PCs are made of a unique combination of chemical and physical properties that make them superior to glass, plastic, and PMMA.

Thermoplastics such as polycarbonate are amorphous and contain carbonate groups. They are tough and have other unique properties. It is relatively easy to mold them. Because of these properties, they are used in many industries.

Strong impact resistance and toughness.

Strong and resistant to impact and fracture, polycarbonates are strong and durable. Computers have a density of 1.2-1.22 grams per cubic centimeter and are indestructible at temperatures up to 140°C.

Transmission

Polycarbonate is a clear plastic that lets 90% of light pass through. For this reason, they are often used in automotive parts. In addition, polycarbonate sheets can be customized based on your color preferences.

Lightweight

Glass is 6 as heavy as polycarbonates. As a result, it is easier to install and more efficient. Transport costs will also be reduced.

UV protection

The benefit of polycarbonates is that they protect us from UV light. If you come into contact with UV light, you will be 100% safe.

The Nature of Optics

Optical applications are well suited to polycarbonates because of their amorphous nature. Their refractive indices are 1.584 for clear polycarbonates

Resistant to chemicals and heat

A high level of acid and alcohol resistance is found in PCs. Note that PCs are susceptible to reacting with diluted alkali. Cleaning PC parts with alkaline soap is not recommended. Polycarbonates hold up to temperatures up to 135°C.